JS SERIES JOINTS AND FITTINGS

FOR VRF - VRV SYSTEMS

JS INNOVARIA FITTINGS FOR VRF - VRV APPLICATIONS

The new line of

JS joints and fittings by INNOVARIA has been designed and developed to facilitate the selection of these components for operators involved in the installation of air conditioning systems using Variable Refrigerant Flow (VRF) systems. The application of our fittings has been standardized into three types, based on the capabilities of the systems.

The fittings are supplied individually.

Our solution allows for the elimination of material and accessory waste.

Copper is a precious metal.

Special attention is given to the new generation of environmentally friendly gases (R744 CO2), for which we have developed and patented a new concept of fittings that can also be used with materials such as K65 and stainless steel to meet pressure requirements that cannot be achieved with standard copper fittings.

The suggested applications in the tables refer to the information provided in the catalogs of major Variable Refrigerant Flow (VRF) air conditioning system manufacturers.

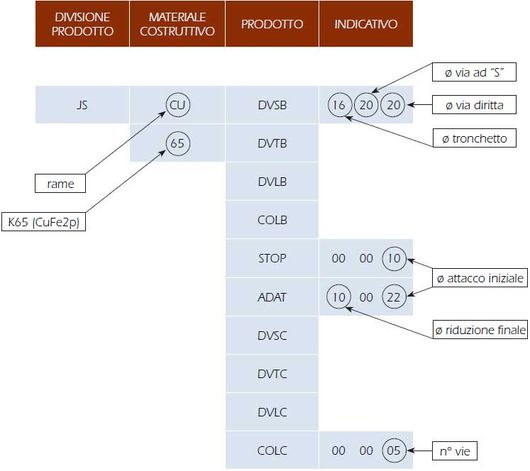

PRODUCT CODING DEFINITIONS

DV_ _ = Branches

DVSB = "S" branches with expansion only

DVTB = "T" branches with expansion only

DVLB = 90° branches with expansion only

DVSC = "S" branches complete with adapters

DVTC = "T" branches complete with adapters

DVLC = 90° branches complete with adapters

COL_ = Collectors

COLB = Collectors with expansion only

COLC = Collectors complete with adapters

ADAT = Adapters

STOP = Stoppers

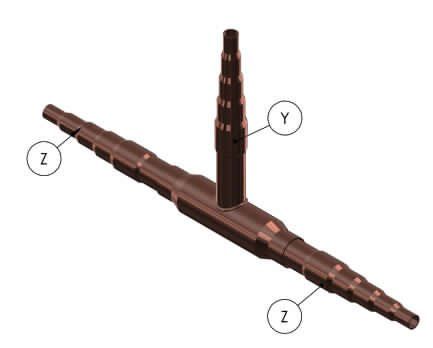

BRANCHES

- The tubes used comply with UNI EN 12735-1 and UNI EN 12735-2 STANDARDS

- The brazing alloy used for WELDING is CADMIUM-FREE, following EN 1044 STANDARD

- Our products are ENGINEERED and MANUFACTURED in accordance with ISO 9001 PROCEDURES

- All INSULATIONS are in CLASS 1 - M1

All BRANCHES are tested at a TEST PRESSURE of 60 BAR

On all branches with a diameter greater than 1", an external reinforcement is mounted on the tube to provide increased resistance to operating pressures.

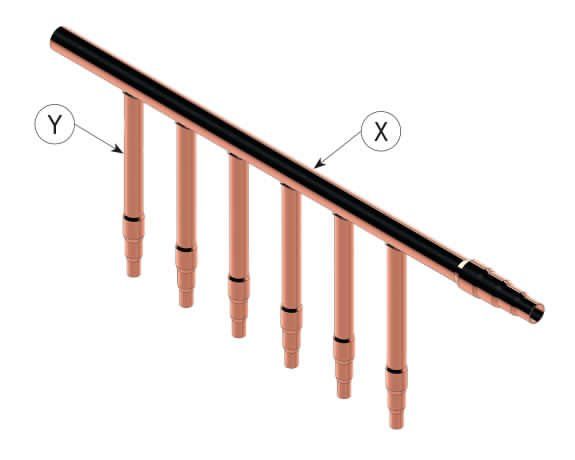

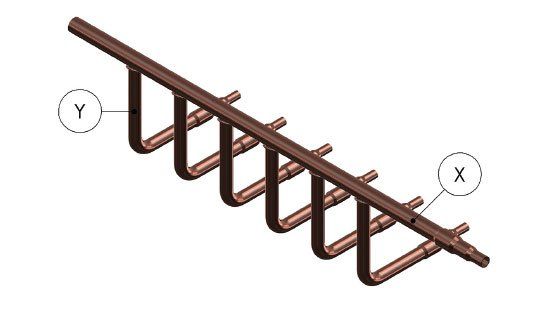

COLLECTORS

The tubes used comply with UNI EN 12735-1 and UNI EN 12735-2 STANDARDS

For WELDING, a CADMIUM-FREE brazing alloy is used, following EN 1044 STANDARD

The ENGINEERING and MANUFACTURING of our products are carried out using ISO 9001 STANDARD procedures

All INSULATIONS are in CLASS 1 - M1

All COLLECTORS are tested at a TEST PRESSURE of 60 BAR

- The tubes used comply with UNI EN 12735-1 and UNI EN 12735-2 STANDARDS

- The ENGINEERING and MANUFACTURING of our products are carried out using ISO 9001 STANDARD procedures